Performance Characteristics: High gloss, good stretchability, and high coverage.

Applicable Substrate: PVC sheet, PMMA, PVC, PC, ABS, and AS

Performance Characteristics: High gloss, good stretchability, and high coverage.

Applicable Substrate: PVC sheet, PMMA, PVC, PC, ABS, and AS

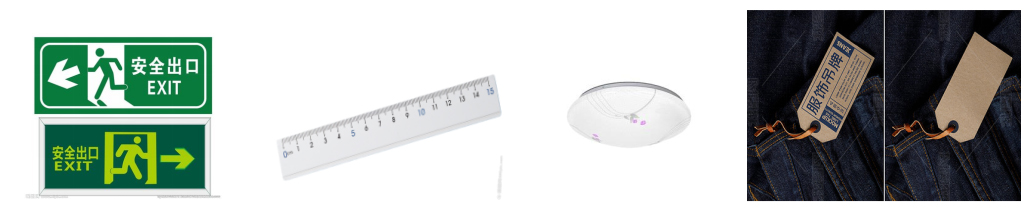

SSEG series ink can be used for printing on substrates such as PVC sheets, acrylic resin boards, styrene, polycarbonate, ABS, and AS. It is commonly used for printing acrylic sheets for safety exits, clothing signs, rulers, lampshades, and other materials. It is also used in the heat transfer printing process of materials such as ABS.

1、 The ink has a high glossiness.

2、 Ink has good high-temperature stretchability and does not crack.

Please use SS-718 diluent (standard) to adjust the printing viscosity

SS-783 diluent (slow drying)

Usually, adding 15-30% dilution solvent to the ink to adjust the viscosity suitable for printing is sufficient for printing.

Ink type: Evaporative drying type

Drying time: 10-20 minutes at room temperature

Heating and drying time: 80 ℃; 5-10 minutes

Please use the above-mentioned solvent or SS-485 cleaning agent to clean the mesh board. If the drying speed of the cleaning agent is too fast, you can mix 10-20% SS-705 diluent to clean it.

Screen type: Please use a ketone resistant screen

Printing conditions:

Ink model: SSEG-911 Black

Printing substrate: PVC

Net Version: 300 mesh

Drying conditions: 80 ℃; 10 minutes

|

Test Project |

Test conditions |

Conclusion |

|

Adhesion |

Baige method, 3M616 adhesive tape peeling |

Do not peel off |

|

Water resistance |

Soak in room temperature water for 24 hours, observe the appearance and adhesion changes of the ink layer |

No abnormalities |

|

Alcohol resistance |

Learning vibration type friction resistance testing machine, soaked in alcohol cotton cloth, with a load of 500g, wiped without falling off multiple times |

>30 times |

|

Oil resistance to gasoline |

Learning vibration type friction resistance testing machine, soaked in gasoline cotton cloth, with a load of 500g, wiped without falling off multiple times |

>10 times |

|

Sweat resistance |

Study vibration type friction resistance testing machine, wet cotton cloth with artificial sweat, and wipe back and forth 200 times with a 500 gram weight load |

No detachment |

|

Acid resistance |

After soaking in 5% hydrochloric acid for 24 hours, observe the appearance and adhesion changes of the ink layer |

No abnormalities |

|

Alkali resistance |

After soaking in a 5% sodium hydroxide solution for 24 hours, observe the appearance and adhesion changes of the ink layer |

No abnormalities |

1、 This series can be mixed with any SS8-000 system.

2、 The ink has a high glossiness, and the stacking degree of the printing sample should not be too high to avoid surface embossing.

1、 Compliant with ROHs, REACH, ASTM F963, EN71-3 (excluding gold and silver), California 65 and other regulatory requirements, and meets the VOCs control requirements of GB 38507-2020.

2、 Please use with caution if there are control requirements for PAHs.

3. SSEG-611 white, SSEG-911 black, SSEG-140 red, SSEG-151 red, SSEG-260 yellow, SSEG-391 blue, and SSEG-037 are low halogen inks.

|

Product Name |

Light resistance |

Product Name |

Light resistance |

| SSEG-611 white

|

5 |

SSEG-911 Black

|

5 |

| SSEG-260 Yellow

|

3 |

SSEG-021 Yellow

|

3 |

| SSEG-214 Yellow

|

4 |

SSEG-391 Blue

|

5 |

| SSEG-083 Purple

|

5 |

SSEG-791 green |

4 |

| SSEG-037 Blue

|

3 |

SSEG-138 red

|

5 |

| SSEG-141 red

|

5 |

SSEG-151 red

|

5 |

| SSEG ink adjusting oil

|

4 |

|

|

Weathering test results: 5: 720 hours without fading 4: 360 hours without fading

3: 180 hours without fading; 2: 130 hours without fading; 1: 90 hours without fading

The above data is obtained from multiple experiments conducted by our company, and we guarantee the authenticity of the information provided. Due to differences in printing materials and construction conditions, our company cannot make any commitments.

Our company has the right to improve our products. Any changes to its specifications are not subject to prior notice.